It’s almost a year since I penned “part 1” of our journey organizing “The Warehouse” for our high school’s theatre department. Now that we have completed the project as best as we were able to, and learned some essential lessons, I am writing the follow up with reflections and lessons learned.

If you are reading this to learn how someone has organized their theatre warehouse/wardrobe, I suggest you read the Part 1 blog post first from last July.

Primary Learning – Need Permanent Labels

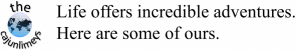

We had chosen a system that relied upon each hanging costume piece having a unique identifier. Based on what we had seen and with concerns about costs, we had chosen to use medical tape.

We realized that we must have labels that definitely would not come off.

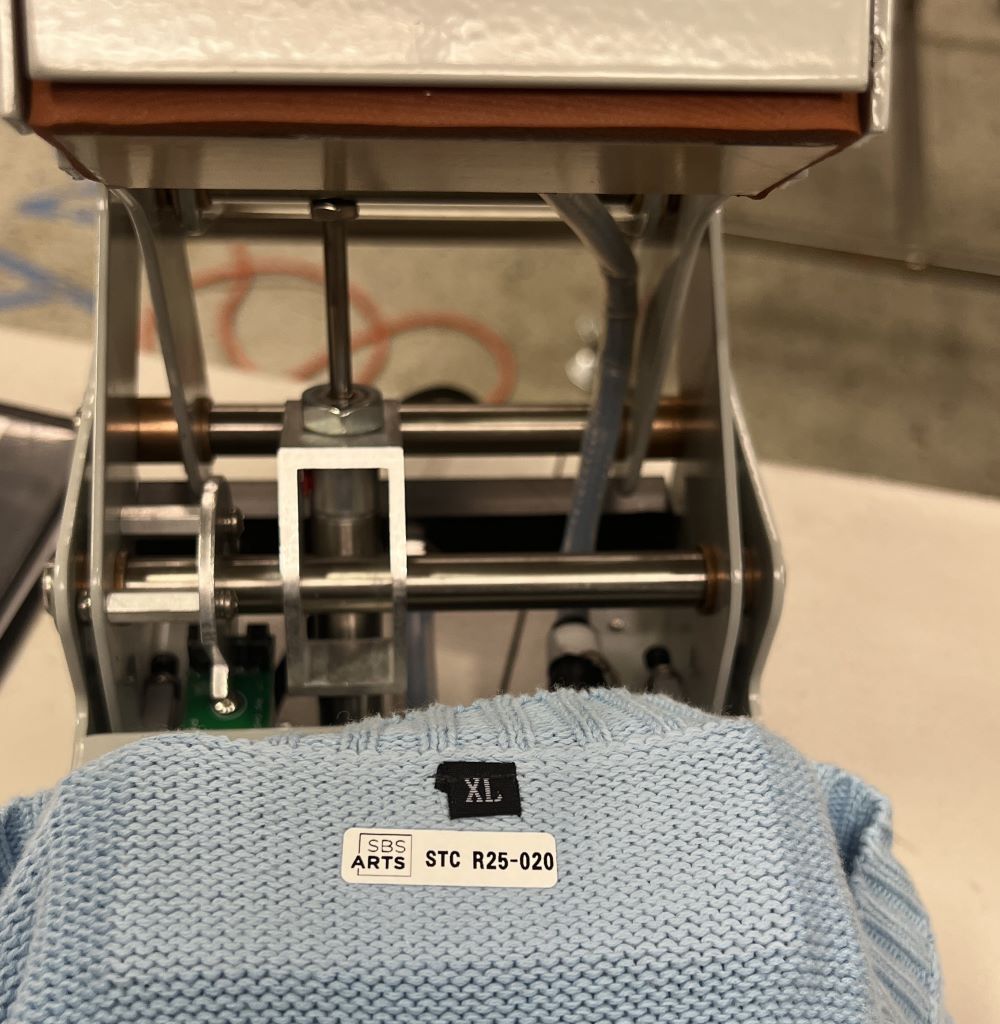

This tape did not stick very well to certain fabrics. Alternatives seemed either expensive or logistically challenging. However, when the first set of costumes returned from drycleaning after the first show, all of the labels were missing. Whether they had fallen off in the cleaning or the drycleaners had removed them, we were not sure, but it made us realize the medical tape was insufficient. We knew someone who ran a drycleaning business, so we got his input (thanks Harry Craig!). He educated us about the heat press and associated labels that drycleaners use to “permanently” label items with a barcode to facilitate their workflows. We needed (a) a heat press machine and (2) special labels, ideally pre-printed to reduce labor and make them look more professional. I researched, spoke with a few vendors, and checked reviews. While I could not find any comments specific to theatre wardrobes, we found what we were looking for.

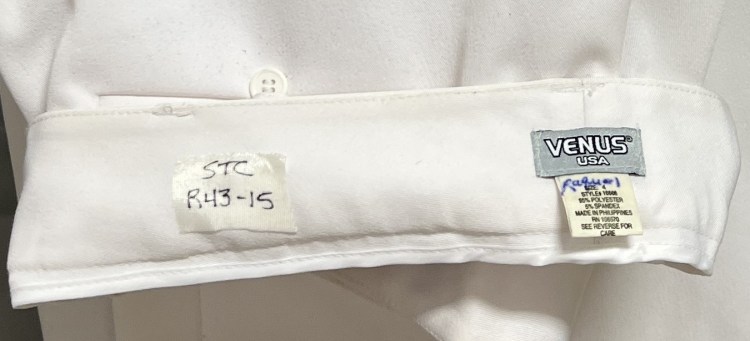

(a) Heat Press Machine. There are several on the market with various bells and whistles. We considered price, our initial usage to press on about 5000 labels, and future labelling by whoever took over from us. We chose EzProducts heat seal press from Florida because it automatically popped up after the programmed amount of time, and their “mini-5” platen was recommended. They supply this or similar models to drycleaning companies across the country, so you could probably find one locally. They also have useful videos on youtube or their website. The unit cost $1100. When we started the project, that was more than we wanted to spend, but we since realized that such an investment was essential for labels that would stay on.

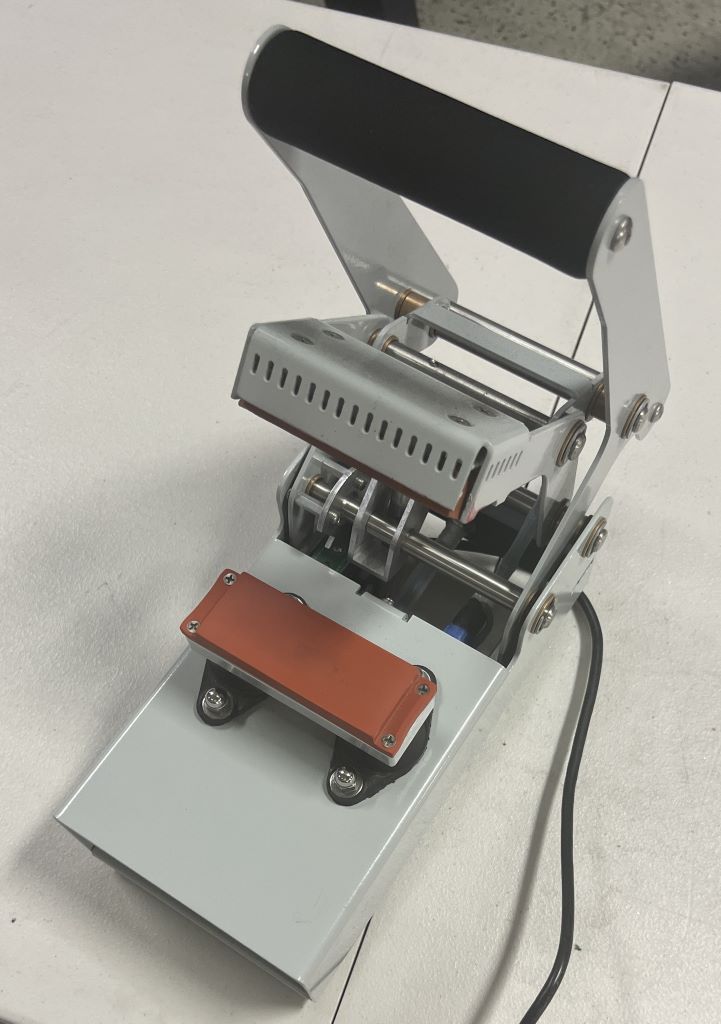

(b) Labels. We wanted labels that (1) could be preprinted, (2) were initially sticky to hold them in place, and (3) could be heatsealed permanently. I considered getting a printer but was concerned how well it would work in the future after storage in the warehouse. Brian Messer at Unitherm (brian@UnithermInc.com, T: 937-278-1900 x323) was extremely helpful in providing samples and helped me create the logo that we put on the label. After a couple of tests, I sent him an excel sheet for the labels that I knew I wanted, with the remaining blank for future labels. The 5000 preprinted labels cost about $600. Much of that cost is printing which could be saved with handwriting all labels, but we believe the professional-looking label helps encourage more careful handling of the costume pieces. These labels required 400 degF for 7 seconds, which was a little different from how the EZPI heatpress was programmed, but they clearly explained how to change the settings when I called their customer support. I recommend both EZPI and Unitherm.

With the heat press and the labels in hand, we were ready to attach 5000 labels! With the costumes already mostly organized, it was quick work for Janet and me to replace the existing labels. However, another pass through all the costumes allowed an additional level of organizing hangers etc. based on learnings. Janet ensured all hangers faced the same direction, and each rack’s numbering started from the same end.

I should share a couple of cautions. First, the heatpress gets hot and can damage fabric. However, the heatpress affected <0.1% of our costumes and then it was on cheap plastic ones or with attached beads. Second, once the label is sealed, you cannot get it off! If it is the wrong label, you can put another one over the top of it, but you cannot remove one.

Reflections on “the system.”

Having used our system for a season of productions, we recognize that it is fit for purpose with limitations. Our priority was something that would help with costume organization in an unstaffed, offsite warehouse and it achieves that. We chose the ‘intelligent” part number as it was fit for purpose. When applying the permanent labels, we would have liked to have reorganized the costumes a bit, grouping similar costumes better. There were opportunities even though we had tried at the beginning. However, because the numbering drove both the website and the printed catalog, it would be a LOT of work to change numbering with the risk of getting it wrong in the catalogs, so we generally did not.

Regarding the catalogs, it remains uncertain how these will be maintained. Permanently attaching a new rack number and ID to new costume pieces remains the priority. Adding such items to the online or printed catalog is clunky as both are homegrown systems. It is straight forward to do. However, it’s unclear how much either of these will actually be used. If such things are used, there will be the motivation to maintain them! I’m more than happy to help when available. This is the cost of having a “free” system!

Additional Value Adds

The desire to organize the whole warehouse as best as one can naturally followed sorting out the costumes. While it will always be a somewhat dirty warehouse with cobwebs, cleaning what we could made the space significantly more welcoming. This led to some unexpected additional opportunities.

The first was that the costume team used the warehouse for their costume decoration. Historically, this would have been done at home. However, with the plentiful well-organized supplies and with clear and clean table space, the warehouse became the preferred location.

The second unexpected opportunity was using the warehouse as a mock-up of the actual theatre to test out the set layout and blocking. We did a blocking run-through with the directors, cast, and crew about three weeks before opening night and we identified some issues that would have been showstoppers. As we had done the run-through three weeks before opening curtain rather than during tech week, we had time to rectify the issues.

To do the blocking run-through, we had to move all of the costume racks to make space, but because they were all organized with defined “homes,” they could quickly and easily be moved back after the practices.

Recommendations:

We were surprised at the impact of the space being clean and well-organized. It meant people wanted to work there. We received comments that the decorated environment was preferable to other workshops. Someone remarked that the smell was much better! It remains a warehouse, but you can wash the floor, tidy, and decorate. Because dust is inevitable, it is best to place as many items as possible under a rack cover or in a clear tote. We tried to avoid cardboard boxes as they deteriorate, don’t protect, and you can’t see what is inside!

We were reminded that the theatre company’s previous warehouse had had a problem with vermin. This emphasized the need to keep this space food-free. This will always be a challenge as it is so easy to throw food wrappers into a trash can. To help with that, it is good practice to take the trash away after every work day. We have no janitor service and not even on-site trash pick up. If trash is taken every work day, it does not build up.

There is a particular challenge in maintaining the organization after shows. The nature of theatre productions is the tremendous crescendo until opening night with a climax on the final night and a rush to pack up and get out of the theatre. However, the production is not complete until every item is put away in the warehouse. This challenge is compounded by delays due to drycleaning or subsequent competitions, but the inventory needs to be left in the same state, if not better, as it was before the production. Theatre companies might have seasons, for example having a break in the summer, so having a focused tidy-up before the summer break is valuable.

The Essential Ingredient

As with most things, people are the essential ingredient. Having completed the initial organization of the theatre warehouse, it requires maintenance. This requires people with the right mindset. The first mindset is to limit access to the warehouse to the few people who understand the value of it being well organized. The second mindset is of the people who have access such that they will maintain it, leaving it cleaner than they find it each time. When one is doing projects in one’s own workspace, you know that no one else is going to use that space so there is less incentive to clean up until it is finished. My garage attests to this! However, in any shared workspace, it is essential that it is cleaned up at the end of every work day, or the mess will get away from you. For this warehouse, we are blessed that some great people will be looking after it for the next season!

A Reflection

We took on this warehouse organization project as it was something we wanted to do. The opportunity came to us at the right time. Our focus was making it sustainably organized. We recognized that much of this was preserving the tremendous value of creations from previous years, but we did not recognize the future impact. The well-organized inventory has helped attract some great people for the future of Second Theatre Company. They bring a diversity of skills and experiences and will help take the theatre experience for our high school kids to the next level. These talented people would not have done our warehouse-organizing project, but we could not do what they are doing.

We estimate that Janet and I spent about 2000 hours on this project between us. We are confident that this will have lasting impact on the theatre, though we believe it already had impact on the productions while we were working on it. First, the school won the One Act Play State Championship in the fall of 2023. While the organized warehouse had no direct impact on this, I believe that having it under control took a weight off the directors’ shoulders, enabling them to give more energy and direction to the kids. Second, the school won a Tommy Tune Award for Outstanding Technical Achievement. This award recognizes the fluidity of scene changes in the production. While having an organized warehouse helped bring everything together, the blocking run-through three weeks before opening night enabled the set team to make adjustments that helped that fluidity. It was the first time that the company had won either of these.

The Directors were very kind to recognize Janet and I with their Arts Advocate Award for 2023-2024. We are hopeful that this might help inspire others.

We give to you, the warehouse:

If You Made It This Far…

… you might be involved in doing something similar. If you are investigating how to organize a theatre warehouse, I strongly recommend visiting as many other theatre warehouses as possible. I did not try hard enough during our initial research. After we had started, we visited the costume department of the Royal Shakespeare Company in Stratford-Upon-Avon that provided some great insight. In Houston, the Houston Ballet would be good to visit. The challenge is working out the solution that fits your particular circumstance. People who run well-organized warehouses are likely to want to show them off! Once you have chosen a direction for your warehouse, it’s difficult and time consuming to change that direction.

If you are looking into how you might organize your theatre warehouse, I hope these blogs have helped. I was unable to find any account like this when I was researching. If you have any questions, please don’t hesitate to reach out to us.